Fluoroelastomers

DAI-EL fluoroelastomer products provide excellent high temperature and aggressive fluids resistance for sealing and fluid transport applications in automotive, oil and gas, chemical processing, small engine, and other harsh sealing environments.

DESCRIPTION

Feartures of DAI-EL fluoroelastomer

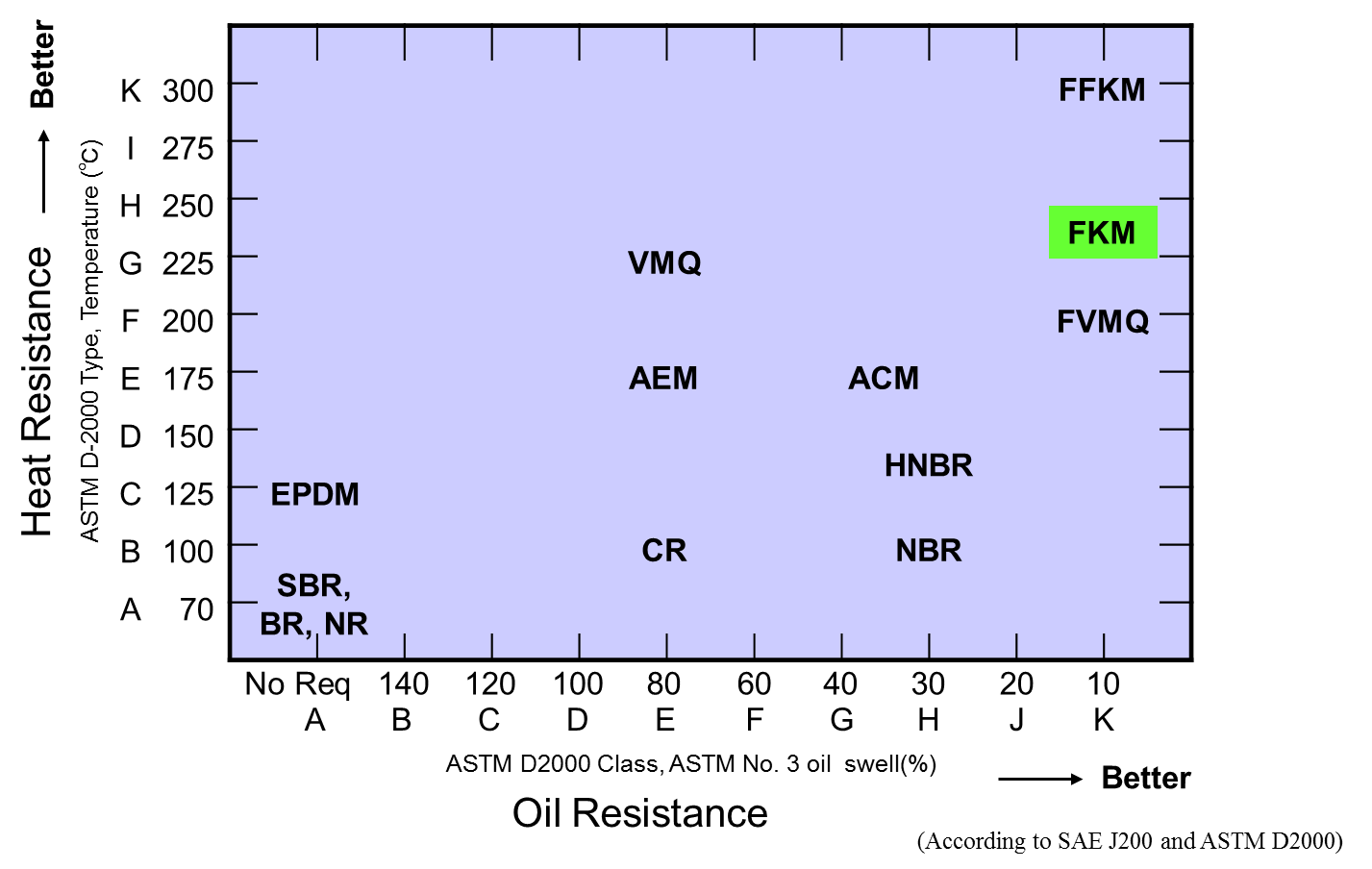

DAI-EL fluoroelastomer products provide excellent high temperature and aggressive fluids resistance when compared with other elastomers.

It also combines the most effective stability to all sorts of chemicals and fluids such as oil, diesel, ethanol mix or body fluid. With low permeation rate, DAI-EL fluoroelastomer allows meeting stringent automotive regulations about gas emission by reducing leakage significantly.

DAI-EL complex polymer design allows stable extrusion and molding processes for every type of technical rubber parts and fitting in a wide range of processing constraints, reducing the risk of failures and increasing productivity and covers the full range of copolymers and terpolymers for bisphenol and peroxide curing as well as specialty elastomers and ready to use compound.

Application

- Automotive: OEMs continue to increase fuel efficiency, reduce emissions, eliminate fluid leaks and improve the efficiency of their systems.

- Chemical plants: Aggressive chemicals, steam, acids, and bases require sealing materials with above average fluid resistance and long-term operability

- Oil & Gas: Drilling processes and other downhole fluids contain additives likely to degrade standard rubber.

- Consumer and wearable: Soft, flexible, non-reactive materials which don't degrade in contact with oils and perspiration are required

- Aerospace: high operating temperatures and high altitudes require superior heat resistance and low-temperature performance

Comparison among rubbers

Effect of Fluorine Content

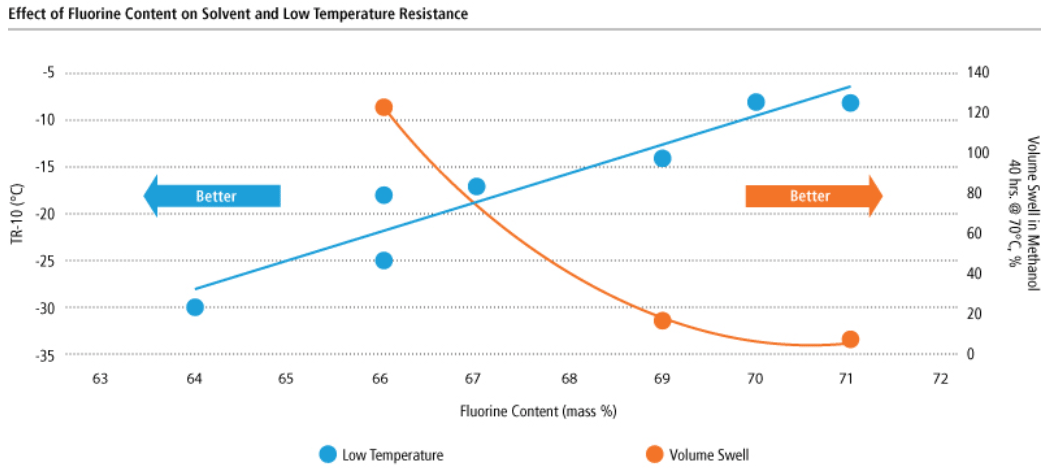

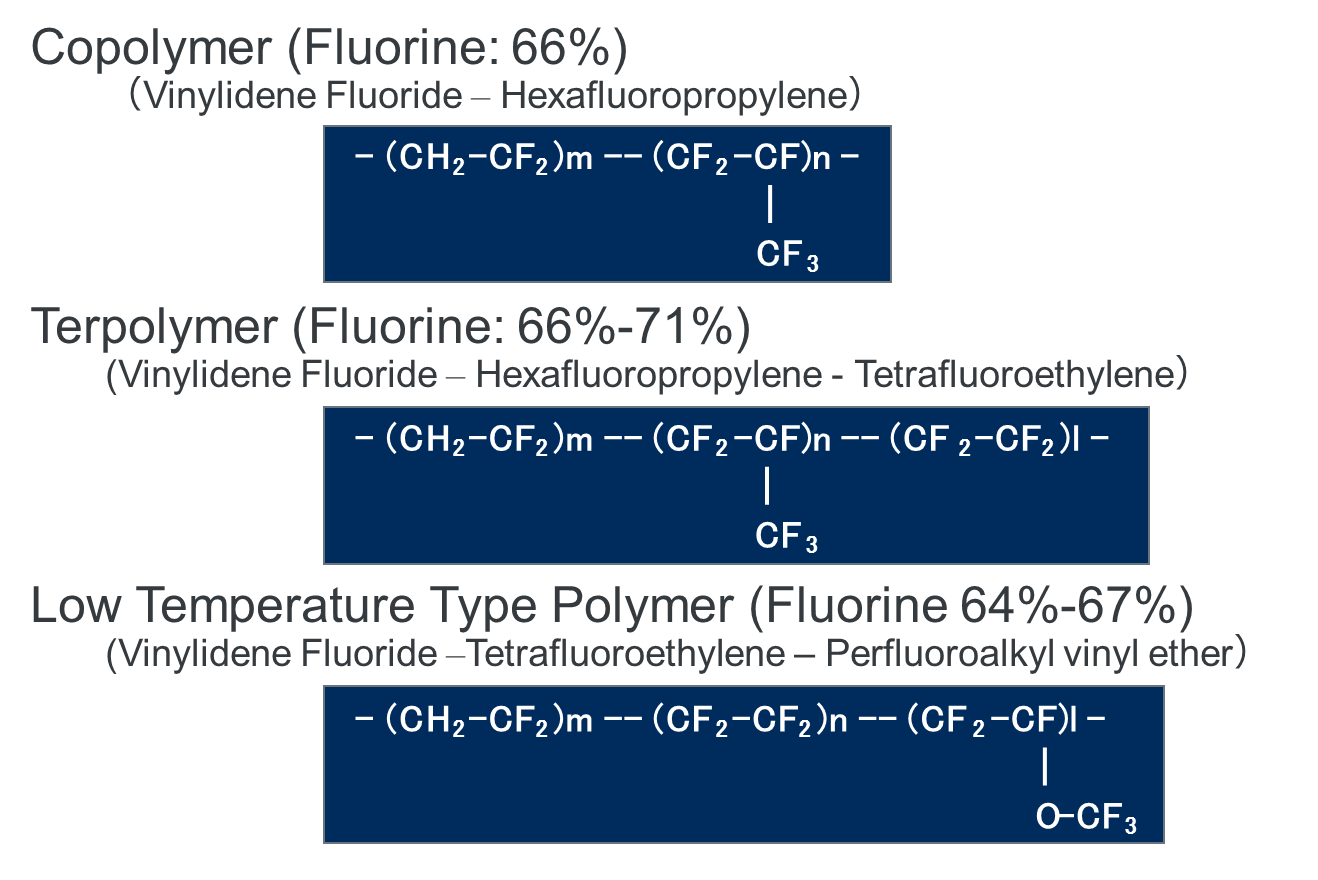

The fluorine content of a DAI-EL grade affects many things, especially low temperature properties and fluid resistance. In general, the lower the service temperature and volume swell of a compound, the better. However, as the chart below depicts, when selecting a fluoroelastomer there is generally a tradeoff between the two properties. For low temperature operating conditions, consider selecting a DAI-EL low temperature or copolymer grade. For sealing against aggressive fluids or other media, consider a 71% fluorine terpolymer or even a perfluoroelastomer.

GRADES & FEATURES

| GRADES | Features | Typical Applications | |

|---|---|---|---|

| Type | Curing System | ||

| Copolymer |

Bisphenol Curable |

Compression set resistance, sealing property | Seals (oil, crank shaft, valve system, bearing), Fuel hose Turbo charger hose, O-ring |

|

Peroxide Curable |

Mechanical properties, chemical resistance, acid resistance, steam resistance, anti-flex fatigue | ||

| Terpolymer |

Bisphenol Curable |

Strong polar solvent resistance, compression set resistance, sealing property |

|

|

Peroxide Curable |

Strong polar solvent resistance, chemical resistance, acid resistance, steam resistance | ||

|

Diamine Curable |

Strong polar solvent resistance, mechanical properties | ||

|

Low Temperature |

Peroxide Curable | Excellent low temperature sealing properties and mechanical properties, acid resistance, anti-flex fatigue | Injector O-ring Diaphragm |

|

Base Resistant Elastomer |

Peroxide Curable | Excellent mechanical properties, base resistance, coolant resistance, engine / transmission oil resistance Acid resistance, excellent anti-flex fatigue |

Seal (oil, bearing ,coolant packer), Turbo charger hose, O-ring |

| Specialty Elastomer |

Liquid Elastomer |

Improvement of processability Reduction of hardness |

Process aid |

|

Thermoplastic fluoroelastomer |

At room temperature, it shows elasticity, and at high temperature over melting point, it shows good flowability like thermoplastics. | Semiconductor O-ring | |

| DAI-EL Compound | Bisphenol Curable Peroxide Curable |

*Cri-tech Custom Compounding | |

|

DAI-EL MORE |

- | Colorability, durability, supple touch, low friction | Wearables Consumer goods |

DOWNLOADS

Catalog

High Performance Fluoroelastomers DAI-EL