Oil and Gas

The dusty deserts in the Middle East, the dark waters of the Gulf of Mexico and the cold regions of Siberia have in common the harsh conditions they impose to oil and gas exploitations. They also command for lower operating costs and increase production efficiency. Daikin Chemicals offers to the oil and gas processing industries solutions to improve competitiveness.

INDUSTRY TRENDS

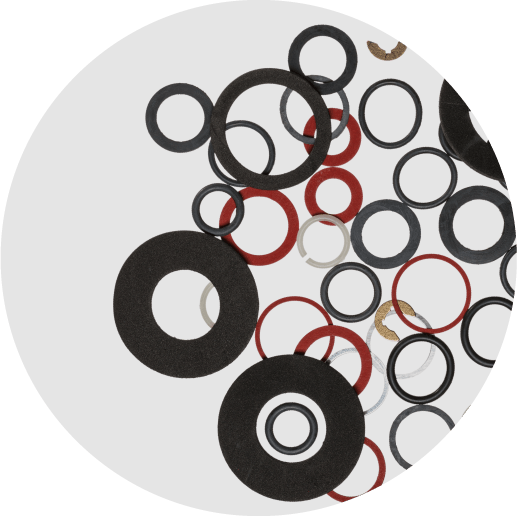

With rising global demand for energy, volatile prices and increasingly severe environmental regulations, the oil and gas industry faces three converging challenges: reduce operating costs, optimize the performance of installations and improve the environmental footprint. DAIKIN confirms a long-term commitment to the oil and gas industry with a wide selection of fluoropolymers and fluoroelastomers meeting the demands for chemical resistance and extreme temperature inflicted to processing parts. Rings, valves or pumps produced with POLYFLON PTFE or NEOFLON fluoropolymers are helping the extraction and handling process to reduce replacement, downtime. They are well suited to resist a variety of demanding chemical, mechanical heat and non-stick surface environment.

DAIKIN high purity PFA resins are fully fluorinated polymers specifically designed for demanding applications. ETFE and FEP polymer grades offer a more affordable alternative to high purity PFA. ETFE also provides better mechanical strength than PTFE, PFA, and FEP. The unique mix of properties of Fluoropolymers are used to prevent corrosion, leak and emission while ensuring a tight process control.

APPLICATIONS

DAIKIN proposes a wide portfolio of fluoropolymers and fluoroelastomers to meet the demands for chemical resistance and extreme temperature range that parts and seals are exposed to in the oil & gas market.