Nonwoven

Nonwovens are usually known for single-use applications or have limited time life. However, usage demanding longer service life are also concerned. Nonwovens are used in a wide range of segments and often require strong barrier protection against liquids. DAIKIN, with a technology base providing hydrophobicity and chemical resistance, is well positioned to serve nonwoven producers and their specifiers.

INDUSTRY TRENDS

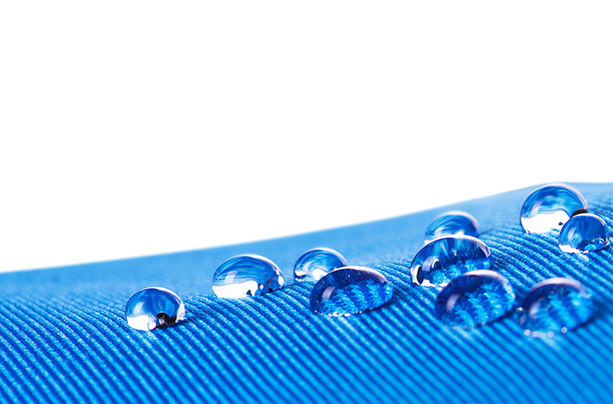

Thanks to their low permeability and hydrophobicity, DAIKIN's UNIDYNE water and oil repellents can be used whether as materials to form the nonwoven fabrics or used as a repellent to protect them.

Supporting the medical segments against infection risks Due to a growing number of nosocomial infections, health care services are engaged in protecting their patients and staff with nonwoven gowns and products. Medical apparel based on or protected by fluoro-based solution, offer barrier protection against fluids and reduce the risk to convey germs. They are employed to repel liquids and keep body parts, wounds or equipment, free from humidity.

The number of automotive parts made of nonwoven materials is increasing and contribute to the vehicles lightweight objectives. UNIDYNE fluorochemicals enable these new surfaces to repel liquid or grease:

- Automotive interior products like floor mats, carpet seating fabrics and door trim padding are kept clean longer. Furthermore, they ensure for the car owner an easier cleaning, thanks to a specific Stain Release property.

- Fuel tanks and mufflers wrapped in repellent-coated nonwoven fabrics lower vehicle noise and offer better thermal insulation. Parts under-the-hood experiences a longer life cycle.

APPLICATIONS

UNIDYNE oil and repellents provide barrier performance for nonwoven surgical apparel and work wear and automotive parts in a variety of industrial applications.

Medical Apparel gowns, packs, face masks, sterilization wipes

Medical segments protected by UNIDYNE offer barrier protection against fluids and reduce the risk to convey germ,